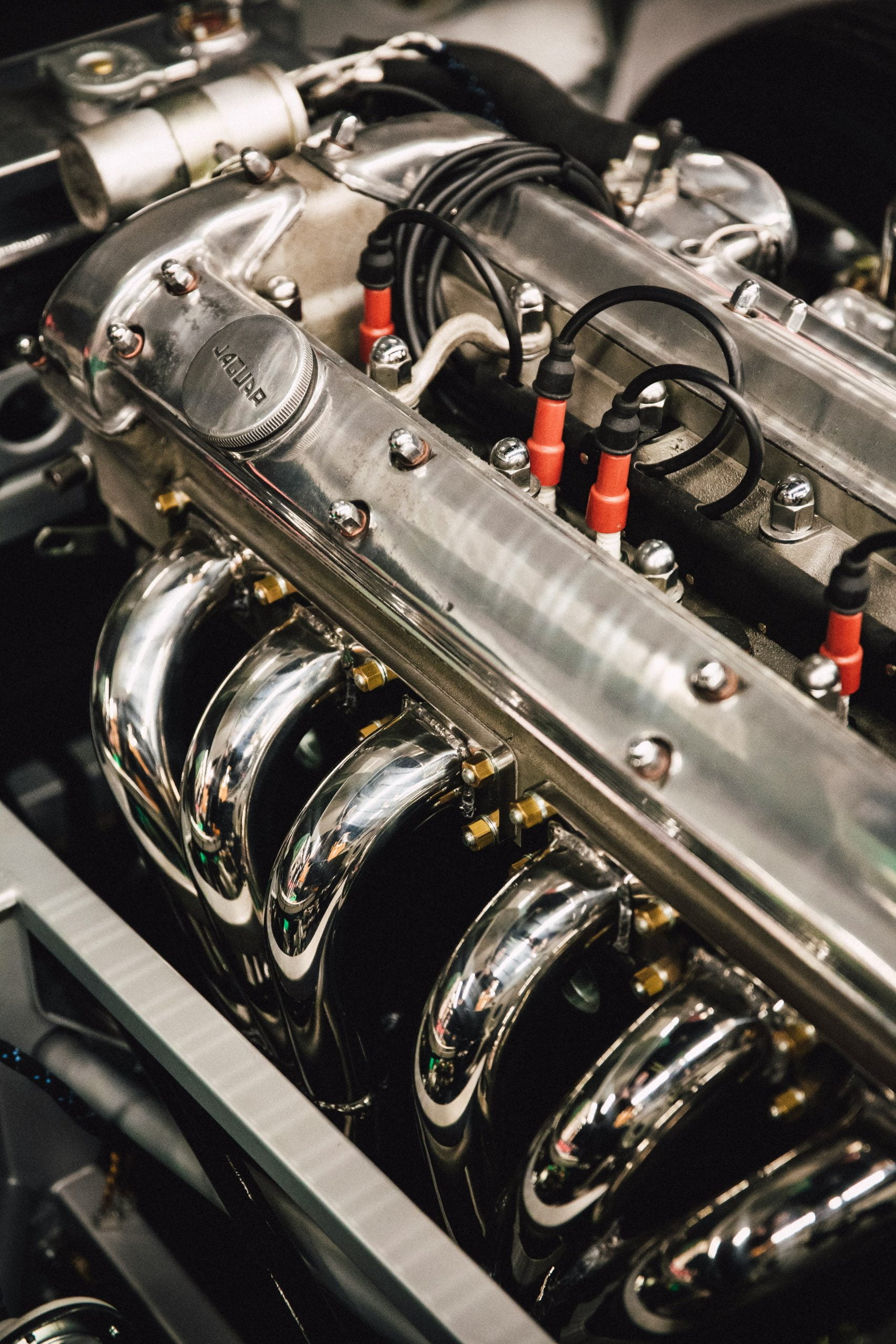

Legendary Jaguar Engine

Jaguar XK Engine

The Jaguar XK engine stands as a testament to Jaguar’s pursuit of excellence and innovation in automotive engineering. Introduced in 1949, this inline-six powerplant was designed under the leadership of Sir William Lyons and engineer William Heynes to power the XK120, a sports car that would redefine Jaguar’s image and set new standards in the industry.

In the post-World War II era, Jaguar recognized the need for a sophisticated engine to match their ambitious XK120 sports car project. Development began in the mid-1940s with a focus on advanced engineering principles and materials. The XK engine debuted with a 3.4-liter inline-six configuration, featuring dual overhead camshafts—a rarity at the time—that allowed for precise valve control and enhanced performance. This design choice not only improved engine efficiency but also contributed to its distinctively smooth operation and potent power delivery.

The Jaguar XK engine introduced a series of revolutionary innovations that set new standards in automotive engineering:

Dual Overhead Camshafts (DOHC): The XK engine was among the first to utilize dual overhead camshafts, a cutting-edge technology in its time. This design significantly improved airflow efficiency by allowing precise control over the timing of intake and exhaust valves. This optimization not only enhanced engine responsiveness but also maximized power delivery throughout the RPM range, distinguishing the XK engine as a high-performance powerplant.

Hemispherical Combustion Chambers: One of the XK engine’s most notable features was its hemispherical combustion chambers. This design promoted efficient combustion of the fuel-air mixture, which led to increased power output and improved fuel economy—an impressive achievement for the era. The hemispherical shape allowed for better airflow and more complete combustion, optimizing the engine’s performance and efficiency.

Aluminum Cylinder Head: The XK engine incorporated an aluminum cylinder head, combining lightweight construction with durability. This innovation improved heat dissipation, crucial for maintaining consistent engine temperatures under varying driving conditions. The aluminum construction also helped reduce overall engine weight, contributing to the car’s handling dynamics and fuel efficiency.

Cast Iron Block: Despite the aluminum cylinder head, the XK engine featured a robust cast iron block. This choice provided strength and durability, essential for withstanding the high stresses of performance driving and ensuring the longevity of the engine. The combination of an aluminum head and cast iron block represented a balanced approach to achieving both performance and reliability.

Twin SU Carburetors: Jaguar opted for twin SU (S.U.) carburetors in the XK engine, a renowned choice for their efficient fuel delivery and smooth operation. The SU carburetors ensured optimal air-fuel mixture ratios across different driving scenarios, enhancing the engine’s responsiveness and overall performance characteristics. This carburetion setup became synonymous with Jaguar’s commitment to engineering excellence and refined driving experiences.

These innovations collectively underscored Jaguar’s commitment to pushing the boundaries of automotive technology with the XK engine. By integrating advanced design principles and materials, Jaguar not only enhanced performance and efficiency but also established a legacy of engineering excellence that would influence generations of sports cars to come.

At its debut, the 3.4-liter XK engine produced approximately 160 horsepower, propelling the Jaguar XK120 to a top speed of 120 mph—a remarkable achievement that made it the fastest production car of its time. The engine’s smooth power delivery and distinctive exhaust note not only established Jaguar as a leader in the sports car market but also captivated enthusiasts and critics alike with its blend of exhilarating performance and luxurious refinement.

The XK engine powered a series of iconic Jaguar models, each contributing to the engine’s legacy and Jaguar’s reputation for engineering excellence. The Jaguar XK120, the engine’s debut model, set new speed records and captured enthusiasts’ imaginations with its blend of performance and elegance. Building upon its success, the Jaguar XK140 refined the formula with improved handling dynamics and enhanced comfort features while maintaining potent performance. The XK150, introduced in 1957, combined powerful XK engine performance with a more refined design and advanced technological features, appealing to a broader range of enthusiasts and luxury car buyers. Perhaps the most iconic of all, the Jaguar E-Type (XK-E) epitomized automotive design and performance excellence when it debuted in 1961. Powered by the XK engine, it became an instant classic and remains highly sought after by collectors worldwide.

The XK engine’s prowess extended to motorsport, where it powered Jaguar to numerous victories and cemented its reputation for reliability and performance. Notably, XK-powered C-Type and D-Type racing cars dominated the endurance racing scene during the 1950s, securing multiple victories at prestigious events such as the 24 Hours of Le Mans. These successes highlighted the XK engine’s durability and ability to perform under the most demanding competitive conditions, showcasing its engineering pedigree and Jaguar’s commitment to motorsport excellence.

Despite its engineering brilliance, the Jaguar XK engine, particularly in older models, has been known to encounter several common issues over time. Cooling system problems, including issues with the radiator, water pump, or cooling hoses, can lead to overheating under high-stress driving conditions or in warmer climates. Aging seals and gaskets may result in oil leaks, particularly from the rear main seal, valve cover gaskets, and oil pan gasket, requiring timely attention to prevent lubrication issues. Wear or failure of timing chain tensioners can cause noise and affect engine performance if not addressed promptly. Electrical faults may occur in older models due to aging wiring and components, impacting ignition and overall engine operation. Carbureted versions may experience fuel system challenges, such as clogged jets or fuel pump failures, affecting fuel delivery and engine performance.

The Jaguar XK engines were predominantly paired with various manual transmissions throughout their production history, including the Moss gearbox initially and later the Jaguar synchromesh gearbox. These gearboxes complemented the engine’s performance characteristics, providing smooth gear changes and enhancing driving dynamics. Automatic transmission options were also available, offering drivers a choice that balanced performance with convenience. Manufactured primarily at Jaguar’s Browns Lane plant in Coventry, England, the XK engine production exemplified Jaguar’s commitment to quality craftsmanship and precision engineering. This facility became synonymous with the brand’s dedication to producing high-performance engines that offered enduring reliability and sophistication.

Production of the Jaguar XK engine spanned over four decades, from 1949 to 1992, leaving an indelible mark on automotive history. Its technical innovations, combined with its performance achievements and motorsport successes, influenced subsequent Jaguar engines and established a benchmark for automotive engineering excellence that continues to resonate within the industry. The Jaguar XK engine remains a testament to Jaguar’s commitment to pushing the boundaries of automotive engineering, blending power, elegance, and technological innovation. Its legacy continues to inspire automotive enthusiasts and collectors, ensuring its place in the pantheon of great automotive engines. Despite its age, the XK engine’s enduring appeal lies in its blend of performance, reliability, and timeless design, making it a cherished part of Jaguar’s rich automotive heritage.